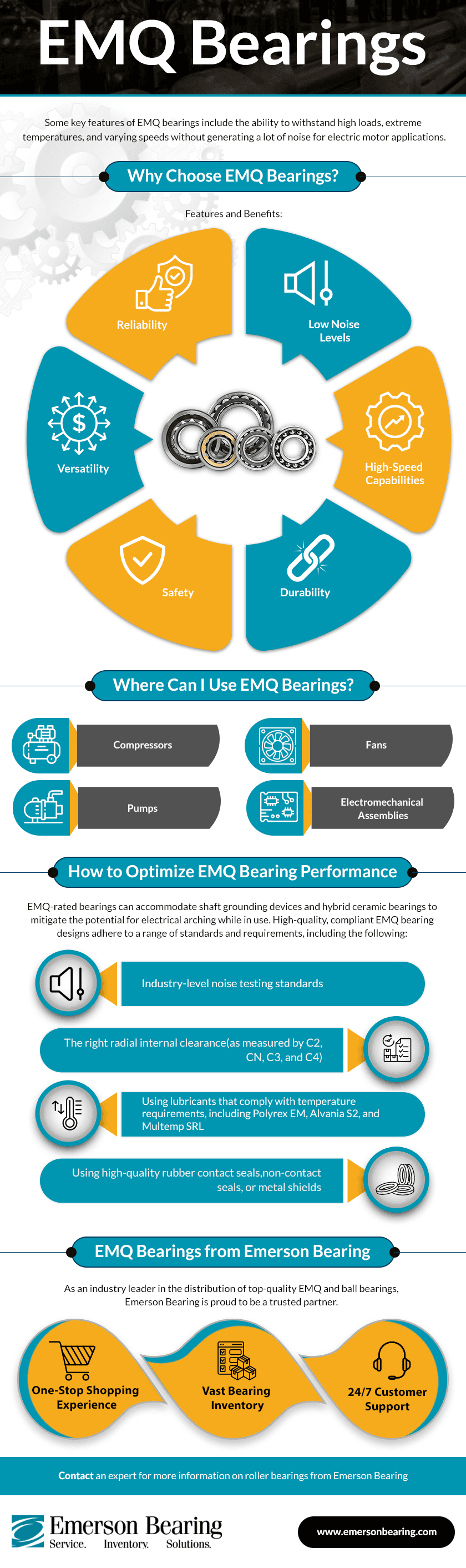

EMQ Bearings

Electric motors require bearings and fabricated components that can support long-term performance. This includes rolling-element bearings that manufacturers develop to minimize disruptive friction and noise.

At Emerson Bearing, we distribute electric motor quality bearings (EMQ bearings) for motors, for compressors, fans, pumps, and dozens of other electromechanical assemblies. We make sure that every bearing is manufactured to very tight tolerances and only use the highest-quality metals, including chrome steel.

Learn more about these high-performing components and how you can optimize bearing performance with the right EMQ bearings.

Optimizing EMQ Bearing Performance

Some key features of EMQ bearings include the ability to withstand high loads, extreme temperatures, and varying speeds without generating a lot of noise. They tend to last longer than comparable bearings and require less maintenance over the component’s lifetime.

EMQ-rated bearings can accommodate shaft grounding devices and hybrid ceramic bearings to mitigate the potential for electrical arching while in use. High-quality, compliant EMQ bearing designs adhere to a range of standards and requirements, including the following:

- Industry-level noise testing standards

- The right radial internal clearance (as measured by C2, CN, C3, and C4)

- Using lubricants that comply with temperature requirements, including Polyrex EM, Alvania S2, and Multemp SRL

- Using high-quality rubber contact seals, non-contact seals, or metal shields

You’ll also want to consider the bearing’s load capacity, shaft and housing fits, and mounting options. We’ve compiled some quick tips to get you started:

Shaft and Housing Fit

Roller bearings must fit precisely between the motor shaft and the inner ring. They should also fit securely between the outer ring and housing. Consider these elements when assessing each product:

- Bearing dimensions

- Load characteristics (such as load type)

- Required running accuracy

- Anticipated thermal expansion of the surrounding parts

Loads

The original manufacturer will typically specify the right bearing based on load type. Find out how much weight or load the motor and bearings can handle throughout the operation, as well as the orientation of the load.

Radial bearings, for instance, primarily handle radial loads (though they can accommodate up to 20% of their total capacity) and exhibit a pressure force perpendicular to the shaft. A thrust or axial load, however, will exhibit force parallel to the shaft.

Proper Mounting Procedures

The most common methods used to mount EMQ ball bearings include:

- The Adapter Method (Withdrawl Sleeve Method). Uses adapter sleeves to mount bearings with a tapered bore

- The Press Method. Involves evenly applying force to mount the bearing. The bearing must be centered for proper placement

- The Thermal Expansion Method. Uses an oil bath heating tank or an induction heater to fit the bearing into place when there is interference between the inner ring and shaft

Regardless of your preferred mounting method, you should start every installation by thoroughly inspecting the motor shaft and housing. Be sure to check for any burrs, flashing, or other defects before inserting the bearings.

Advantages of Using EMQ Bearings

EMQ bearings are built for electrical assemblies and applications, meaning they can offer better overall performance than generic or standard bearings. Consider these unique advantages when making your final selection:

- Durability. EMQ bearings are made from strong, high-quality metals that promote tight fabrication tolerances and help the bearings last longer, even in high-heat environments.

- Efficiency. Our EMQ bearings are designed for optimal performance, resulting in fewer malfunctions, repairs, and part replacements.

- Reliability. Operators can rely on electrical motors to perform more consistently when using EMQ bearings.

- Safety. The unique fabrication process used to develop EMQ bearings helps reduce the risk of electrical arcing. This helps avoid unexpected maintenance costs.

- Versatility. We have a wide range of EMQ bearings and bearing installation methods available. Our trained specialists can recommend the right component for any application based on your load requirements and other particulars.

Emerson Bearing: A Leading EMQ Bearing Manufacturer

At Emerson Bearing, we design and develop high-quality bearing solutions, including a range of EMQ bearings. We’ve served clients around the world for over 50 years, developing roller and ball bearings that offer lasting performance.

Contact us today to learn more or to request pricing details. You can also use our online product selector to quickly find the bearings solution you need.